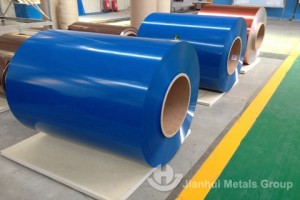

3003 H24 color coated aluminum coil for table panel is the most broadly utilised aluminum alloy. It truly is produced up of aluminum, copper, iron, manganese, silicon and zinc. It can be normally utilised because it has excellent resistance to corrosion and is moderately sturdy. The 3003 aluminum coil is 20% stronger than 1100 grade alloys because it is fused with manganese.

Because it?ˉs not heat treatable, it must be strengthened using cold functioning alone.

Essentially the most popular applications for the 3003 H24 color coated aluminum coil for table panel are for fuel tanks, sheet metal work and other forms of projects that will need a metal that may be stronger than the 1100 series aluminum. In some instances, it is actually made use of for cooking utensils, refrigerator panels, gas lines, storage tanks, garage doors, builder?ˉs hardware and awning slats.

The machinability from the 3003 H24 color coated aluminum coil for table panel is considered excellent for becoming an aluminum alloy. It’s readily machined for the distinctive applications. It might either be formed working with standard hot operating or cold functioning. It?ˉs also attainable to use traditional welding approaches to shape 3003 aluminum. It can be from time to time welded to other aluminum alloys, like 6061, 5052 and 6062, which must have an AL 4043 filler rod.

AL 3003 H24 color coated aluminum coil for table panel isn?ˉt heat treatable, but it could be forged with heat that?ˉs involving 500 and 950 degrees Fahrenheit. When working with heat within this range, the aluminum might be hot worked simply. Nonetheless, it is actually readily cold worked, which can be done employing standard methods. When annealing the alloy throughout or immediately after using cold functioning approaches, it ought to be performed at 775 degrees Fahrenheit. This will give it sufficient time for you to completely heat prior to being air cooled. The only method to make this alloy tough is together with the use of cold operating. It might also be deep drawn, spun or brazed.

Last article: economical aluminium circles prices for making notice plate

Next article color coated roofing coil PE PVDF aluminum coil for kitchenware decoration