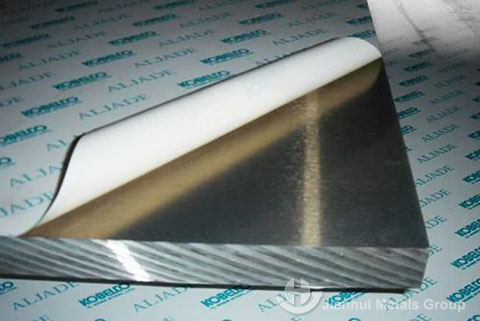

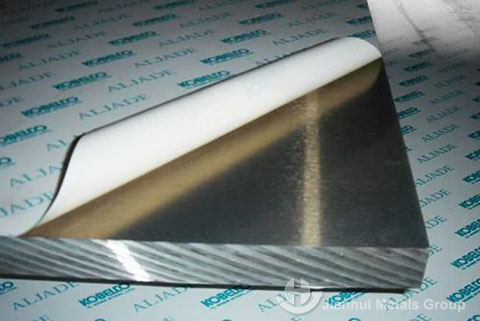

Alloy 2024 Aluminum Plates with ASTM B209 EN JIS standard

Alloy 2024 aluminum plates are perhaps the best known and most widely used aircraft alloy. Since it exhibits high yield strength and relatively good fatigue resistance, it is readily used on structures and parts where good strength-to-weight ratio is desired. Because of its good machinability and superior grain structure, Alloy 2024 plate is essential for precision fittings and parts. Though this alloy does not have good corrosion resistance, welding by resistance method is feasible. Typical specifications are ASTM B209, AMS-QQ-A-250/4 and AMS4037.

The

Alloy 2024 aluminum plates is most often used in the aircraft industry. It is well-suited for this type of application due to its high strength to weight ratio, good fatigue resistance and ease of machinability. The aerospace industry is only one of the areas that can take advantage of this alloy. It is also suitable for use in the transportation industry as well as the computer industry.

The 2024 Aluminum plate can be used to make fuselage structures, wing tension members, precision fittings, missile parts, truck wheels, couplings, hydraulic valve bodies, fuse parts, pistons, gears and shafts, nuts, bolts and other hardware.

The benefits of the aluminum plate include its tensile strength and shear strength. The tensile strength can exceed 50,000 psi, which makes it ideal for the aerospace industry and other industries where this type of strength is important. Its fatigue resistance properties also make it more durable than most other types of materials.

The machinability of the

Alloy 2024 aluminum plates is another benefit. It can be formed into the exact shape, size and dimension that is needed. The high speed machining of the product produces accurate results.

The 2024 aluminum plate does not offer good corrosion resistance when welded. The heat caused by the welding process can degrade the aluminum plate, thus crippling its performance. If there is a need for welding, it is recommended that only spot welding is used with the aluminum plate to maintain as much of the original integrity as possible.

Fuselage structurals

Wing tension members

Shear webs and ribs

Precision fittings

Truck wheels and parts for transportation